Microcut Transcend Paper Cutter Update Kit

The Microcut® Transcend Update Kit, once applied, controls all clamping, cutting, and safety pin operation, monitors and sends knife motion and position status, interfaces with multiple safety curtain options and is all controlled by the power of a Microcut X-12PLUS. The Microcut Transcend Update Kit can cost effectively bring your old paper cutter up to modern operational and safety standards extending the life of your investment.

The microcut Transcend uses the powerful Microcut X-12PLUS backgauge control system for its operator interface.

Microcut Transcend Install Examples

Below are examples of customer machines that have been updated with the microcut Transcend Paper Cutter Update kit

Polar® X-XT Paper Cutter

Polar® E-ED Paper Cutter

Polar® EM-EMC Paper Cutter

Wohlenberg® MCS Paper Cutters

Wohlenberg® CUT TECH Paper Cutters

Challenge® Paper Cutters

ITOH® Paper Cutters

Schneider® Paper Cutters

Perfecta® Paper Cutters

This is just a sample of the popular brands and model paper cutters the Microcut Transcend updates.

Don’t see your brand or model listed above?

No worries, Contact us to let us know what paper cutter you need to update.

Why choose the Microcut?

Here are six reasons for you to consider the Microcut Transcend for your paper cutter:

- Reduces your reliance on parts that are no longer available

- Avoids costly replacement parts

- Boosts your paper cutter accuracy

- Brings your paper cutter up to modern safety standards

- Microcut X-12PLUS units allow paper cutters to convert .JDF files as it is CIP 3/4 enabled

- Extends the life of your paper cutter

The Compatible Brands

Here are the brands that the Microcut Transcend can be installed. Don’t see your paper cutter brand? Contact Us.

- POLAR

- PRISM

- SABER

- CHALLENGE

- SCHNEIDER

- SCHNEIDER ENGINEERING

- DEXTER LAWSON

- HARRIS SEYBOLD

- PERFECTA

- ITOH

- PIVANO

- MAXIMA/ADAST

- WOHLENBERG

- BAUM CUT

- EUROCUTTER

How the Microcut Transcend Update Kit Works

Below is an illustration of how the Microcut Transcend is incorporated on a paper cutter.

1. H4 CCS Drive Box

Complete Cutter Control System that positions fast and accurately the back-gauge, monitors knife, controls clamp, air table, main motor, knife change, safety curtain, safety pins and optional peripheral equipments

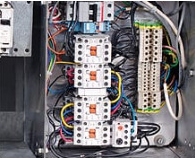

2. Power Panel

Interfaces the AC and DC power components such as main motor, air motor, clutch, hydraulic valves, front display panel, Circuit breakers and any other component that would require power.

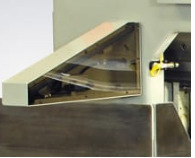

3. Knife Position Monitor (KPM)

Monitors and sends knife motion and position status to the control system.

4. Safety curtains

The system can interface with multiple curtain options.

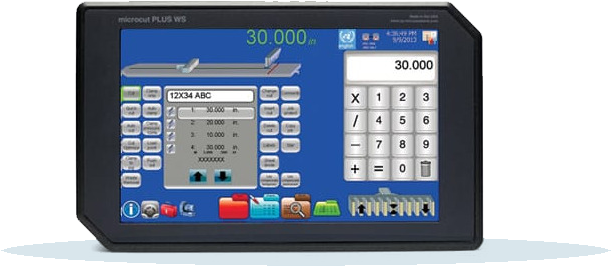

5. Screen and Panel

The Microcut 12” color touch screen display is incorporated into a panel that fits into the front of an existing paper cutter.

Microcut Transcend Brochure Download

The power of Microcut X-12PLUS

The Transcend control interface runs on the fully featured Microcut X-12PLUS.

The C&P Microsystems Microcut X-12PLUS backgauge control system is designed to automate backgauge movement for the Transcend. The Microcut X-12PLUS model includes a state of the art drive control system with an intuitive, easy to use color touch screen operator interface integrating CIP3/4 compatibility.