CHM Precision Paper Sheeter

Quick. Precise. Efficient.

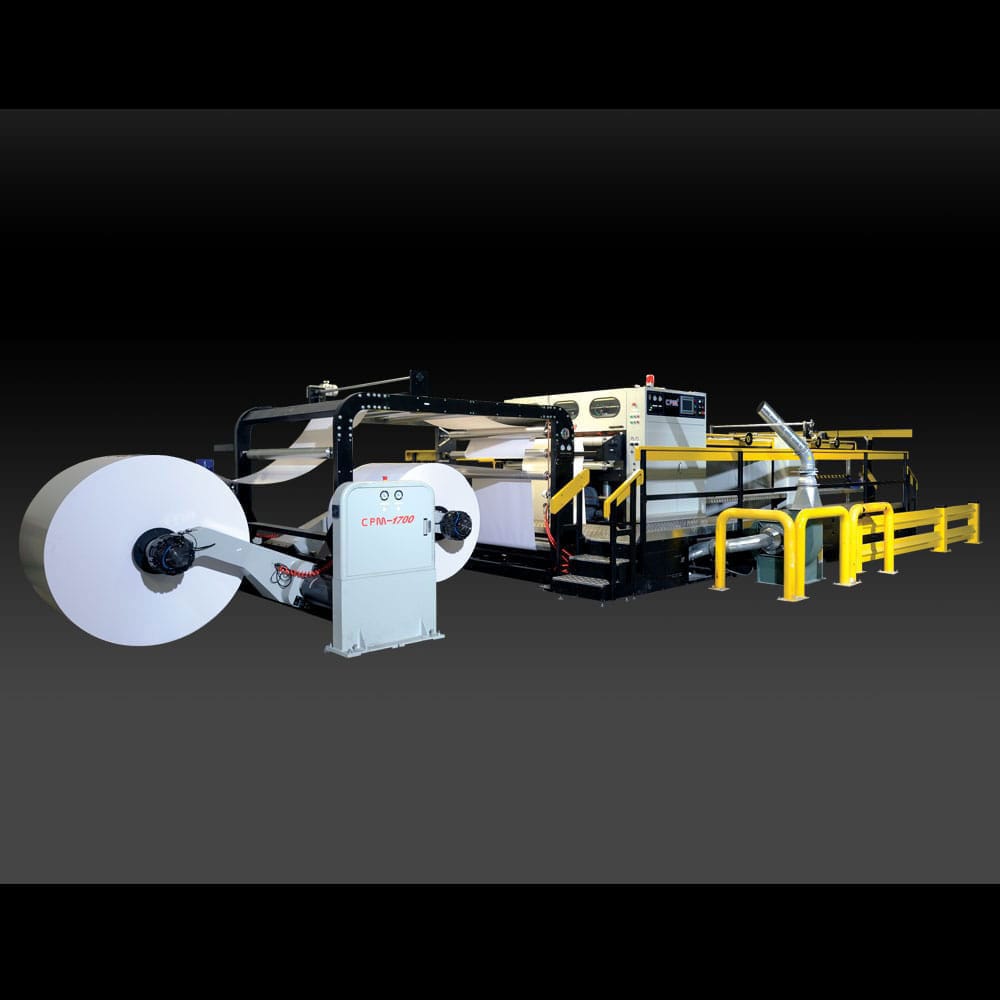

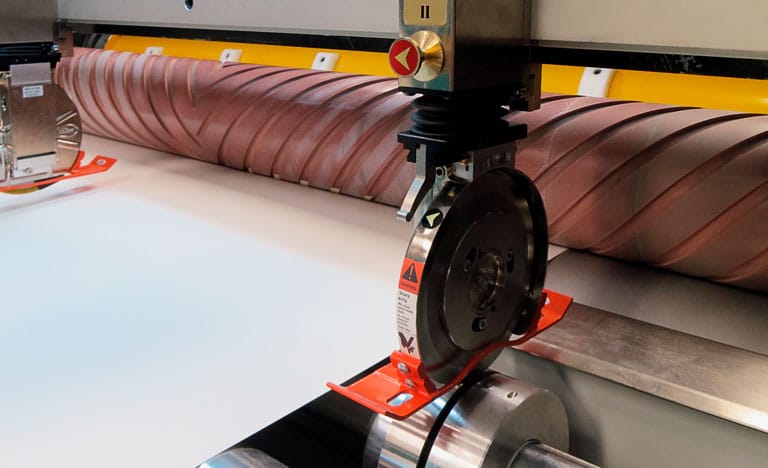

Colter & Peterson is working with CHM - the leading paper sheeter manufacturer in Asia - to offer the most cost effective, space efficient synchro fly twin knife and fixed bed knife sheeters available today.

CHM, which produces over three hundred machines annually, recently built a new manufacturing complex outside of Shenzen, China with a half million square feet of production capacity. Couple that capacity with Colter & Peterson’s experience working with Asian vendors to ensure CHM’s sheeters meet American standards, and you’ve got a winning combination. Reflecting our confidence that CHM Precision Paper Sheeters are the best in the market, each machine comes with a full two-year warranty.

“With this machine, the make-readies are quicker and that’s important because we can change the web width up to 10 times per day.”

Feature Highlights

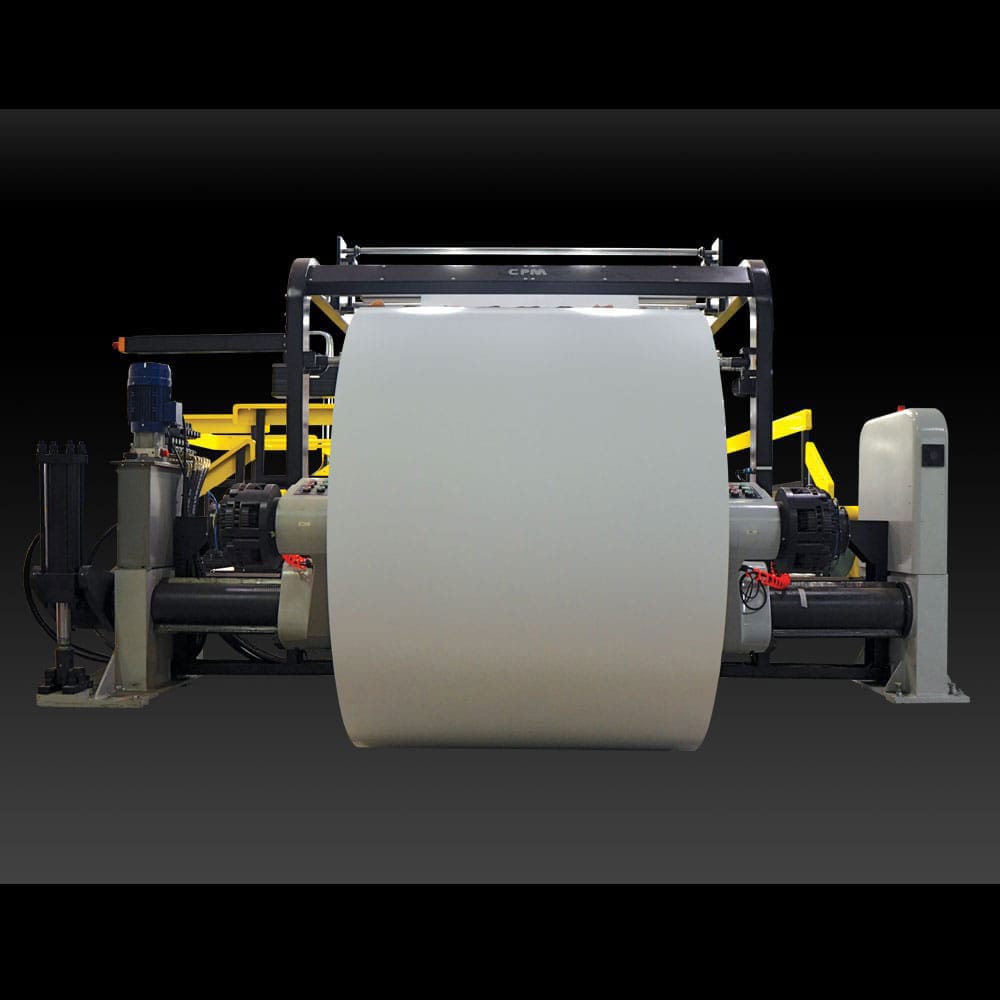

Dual shaftless back stands with American-made Montalvo web tension controls and pneumatic brake units are standard. Easy to replace friction pads and an enclosed cooling fan are part of every Montalvo braking system.

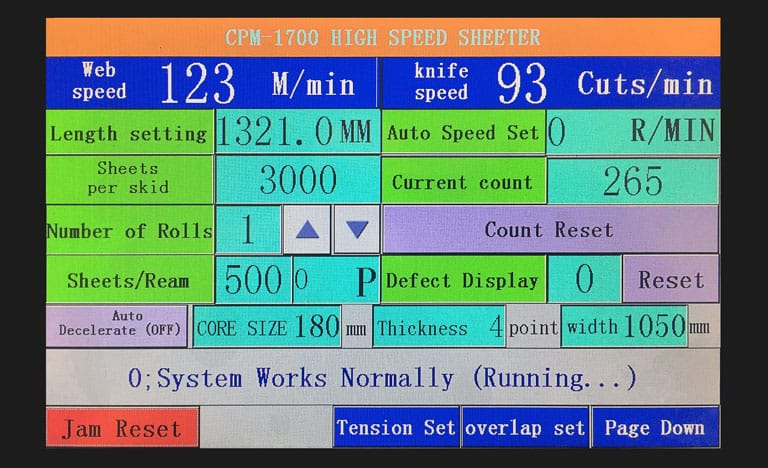

10” Siemens touchscreen controls are used to set and display sheet size, count, cut speed, delivery overlap, and more. The touchscreen controls work in conjunction with a Siemens PLC and Siemens Servo synchro cutting motor control unit to adjust twin knife cut size.

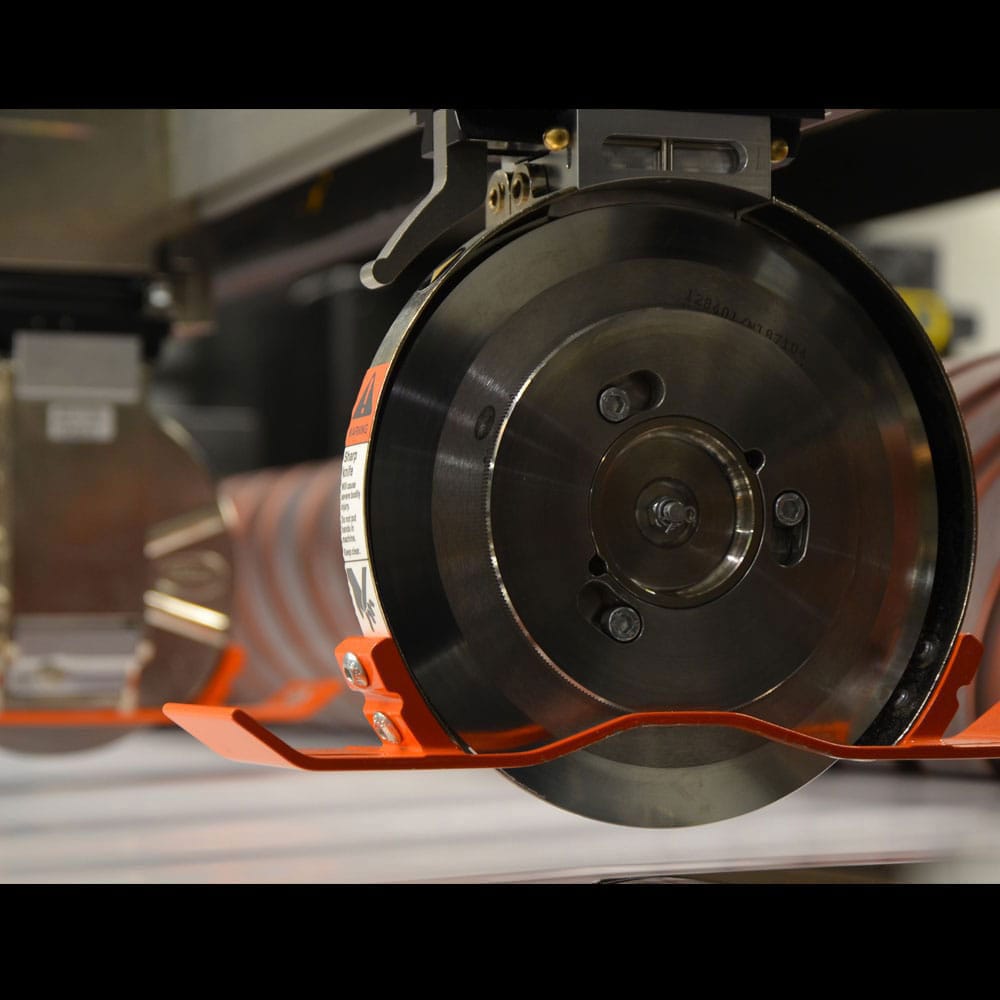

Three Tidland Class II Slitting units with double-sided anvils are standard on all CHM sheeters. Split anvils and Class III units are also available for heavy board slitting.

Individually programmable set point closed loop web tension controls are used for each roll. This Montalvo system shows actual web tension continuously for each layer.

Features, Specifications, & Optional Features

- Roll stand taper chucks accept 8”-12” & 3”-6” cores

- Infeed section with 4” rollers, 6” roller option for heavy board

- Remotely adjustable motorized decurl for each web

- Reject gate is standard

- Anti-static control bars fitted as standard

- Centrifugal locking removable chucks

- Coast dual web steering guide with auto-centering

- Up to 72” high skids can be piled

- Up to 84” diameter, 6,000 lbs. rolls can be accommodated

- Pile removal from side of delivery can be accommodated using our swinging catwalk

- Continuous discharge available

- Auto splicing available

- Cutting accuracy of +/- .020”

- Maximum cutting speed of 1,000 ft/minute or 300 cuts/minute (subject to density)

- 57” and 67” machine widths available

- 18” to 82” adjustable sheet lengths available

- Capable of cutting paper and board from 100gsm to 1000gsm

- Standard 51” high skids can be piled

- Standard 72” diameter, 5000 lbs. rolls can be accommodated

- Vacuum brake for sheet to control overlap

- Two sets of carbide knives

- Roll skates with tracks provided

- Catwalk surrounding entire machine

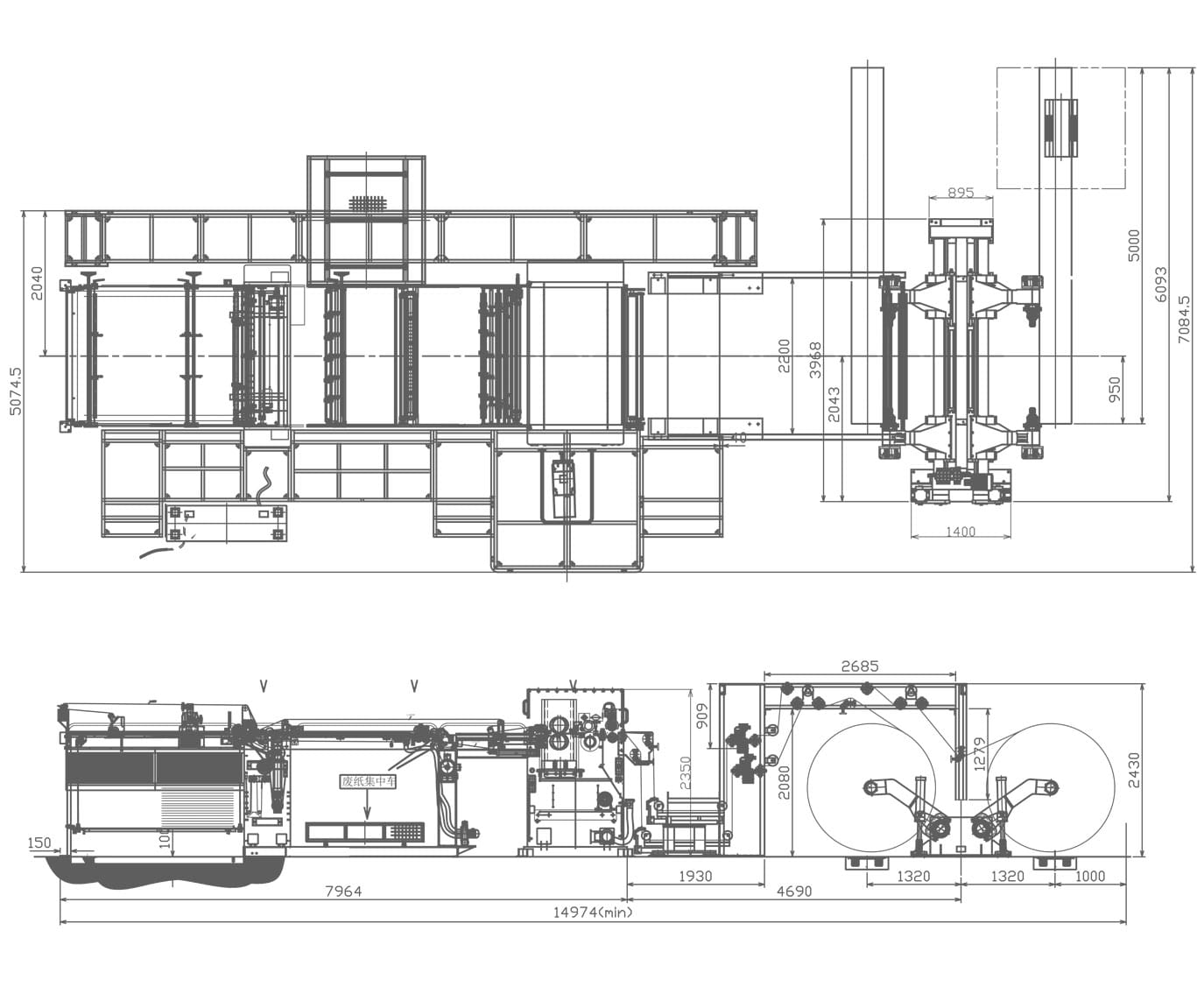

CHM Precision Paper Sheeter Machine Specifications