If you have ever watched a NASCAR or Formula 1® race crew in action, you’ve seen the magic that happens when you put the right tools in the hands of the right people. Speed and efficiency win races. When it comes to moving your deadline-driven print jobs across the finish line, the same fundamentals apply.

One of the best ways to keep your company competitive is to optimize workflow. It’s important to review your entire process. This includes your paper cutter. It’s a core element in your production line. It’s also one of the places where you can readily boost speed, efficiency, and productivity.

Build out your paper-handling system

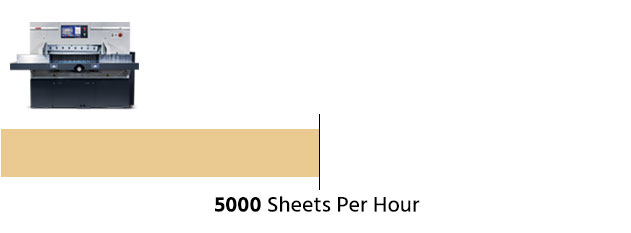

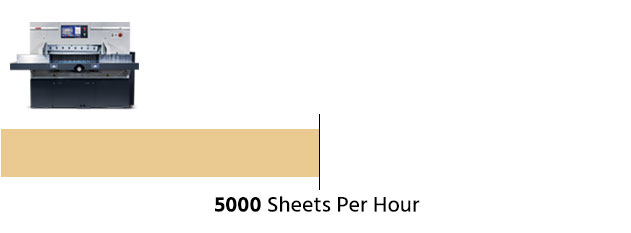

Paper Cutter

Start with the guillotine cutter. It’s the heart of the system. If you already have a rugged, CIP 3/4 standards paper cutter with an accurate back gauge, you’re off to a great start. If you have an oversized table for staging material, all the better. Although most paper cutters can handle 5,000 sheets per hour, there are ways to greatly improve productivity. And you don’t need to change your cutter to do it. Getting the most out of your cutting process often means building a paper-handling system that ergonomically supports the paper cutter operator. Adding a stack lift, jogger, and unloader can double your current cutter’s productivity. The best part is you can do it step-by-step, one piece at a time.

Step up to greater productivity

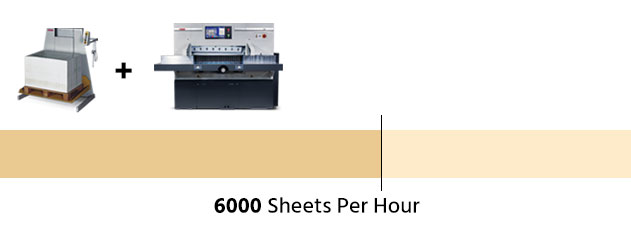

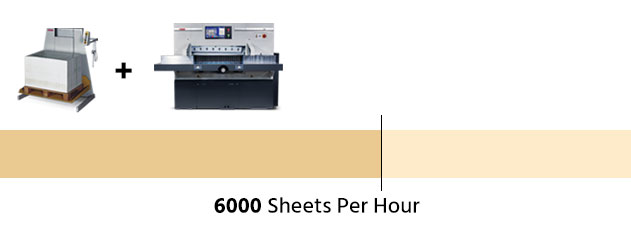

Stack lift

Adding a stack lift gives the operator an easy, efficient way to raise and lower materials. Using an infrared beam system, a stack lift automatically brings materials to the right height to pick up or drop materials. A stack lift can be loaded or unloaded with a pallet jack, making it more economical than a forklift. Adding a stack lift can improve operator efficiency by 20% to 6,000 sheets per hour.

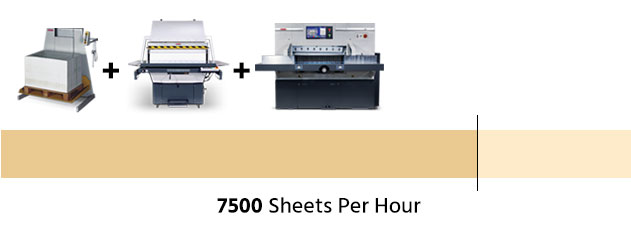

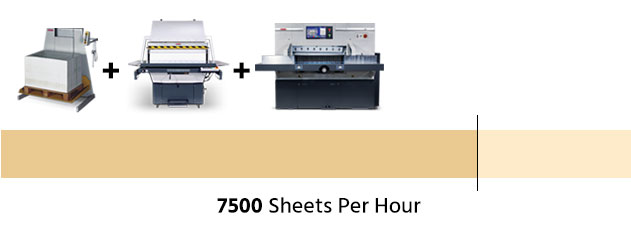

Jogger

A jogger is a very effective way to prepare paper for cutting. Using vibration, gravity, and a squeeze roller, joggers align sheets and remove air to improve cut quality and accuracy. Joggers do their work away from the clamp of the cutter. This helps improve safety. Installing a jogger along with a stack lift can increase productivity by an additional 25%. This allows an operator to process 7,500 sheets per hour.

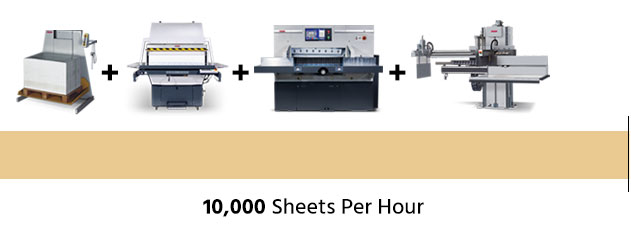

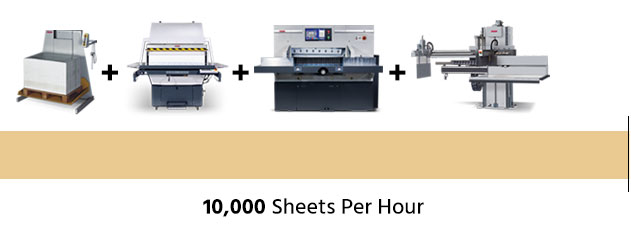

Unloader

Unloaders move completed work from the table and place it directly on a skid. This clears the way for paper cutter operators to do what they do best, cut. Accelerating the unloading process adds greatly to overall workflow efficiency. Fitting a stack lift, jogger, and unloader to your paper cutter boosts productivity an additional 40%. With this system, the operator can handle 10,000 sheets per hour.

Expand your crew

After all the equipment is in place, there is one more thing you can do to supercharge your paper cutter. Hire a support assistant. This person would move skids, load the stack lift, jog reams, and clear completed work from the cutting line. Having a support assistant allows the operator to stay focused. Working as part of a two-person team, a paper cutter operator can cut about three times more material—and do it with increased accuracy.

Getting started

Improving workflow efficiency helps boost your bottom line. But building the proper system takes planning and investment. At Colter & Peterson, we’re here to help. We can review your current system, assess your potential for growth, and help identify the right equipment for your needs.

Feel free to contact us with any of your industrial paper cutter questions.